- 0755-21675210

- acdrive@micno.com.cn

The MDB brake unit series uses advanced power control technology to develop high-performance brake products in combination with a new generation of IGBT power devices.

The power brake unit can release the electric energy generated by the motor during the braking process through the power resistor (brake resistor) to generate sufficient braking torque to ensure the normal operation of the inverter and other equipment.

The MDC series brake unit is used in the inverter to transfer the regenerative energy generated by the motor to the brake resistor for release. When a motor brakes, the regenerative energy generated during the braking phase will be fed back to the higher-level inverter device, which will cause the DC bus voltage of the device to rise, affecting the safety and normal operation of the device. The braking unit for inverter will greatly consume this energy to protect the inverter.

The MDC braking unit for inverter is connected in parallel to the DC bus of the inverter. The bus voltage is limited to an acceptable level and the brake regenerative energy is transferred to the external braking resistor.

The braking resistor releases the brake energy in the form of thermal energy.

The brake unit for motor is connected directly to the frequency converter or inverter via the DC link terminals. When the DC bus voltage reaches a predetermined limit, the brake unit is automatically turned on to prevent the DC bus voltage from continuing to increase. The operation of the brake unit is independent of the frequency converter or inverter.

The brake power brake unit electronics are powered by the DC bus voltage.

In order to increase the braking power, the braking unit for VFD can be connected in parallel.

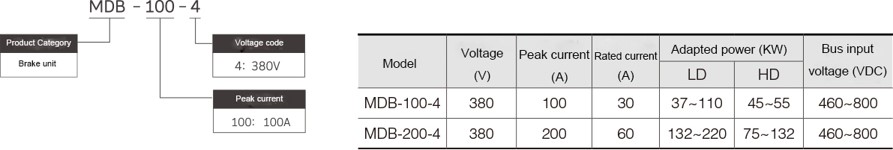

The MDC dynamic braking unit is available in 100A and 200A specifications. The product voltage rating covers both 220V and 380V voltage levels.

Rated Output | Maximum discharge current | 100A(10%ED,10s;MDB-100-4);200A(10%ED,10s;MDB-200-4) |

Rated discharge current | 30A (continuous; MDB-100-4); 60A (continuous; MDB-200-4) | |

Brake starting voltage | 380~460VDC (5 files optional) | |

Hysteresis voltage | About 16V | |

Power Supply | DC supply voltage | 460~800VDC |

Protection Features | Radiator overheat protection | Protected by thermistor |

Display during charging | The main circuit DC voltage reaches about 50V. The charging indicator (CHARGE) lights up | |

Environment | Ambient temperature | -10℃~40℃, derated 4% when the temperature rise by every 1℃(40℃~50℃) |

Humidity | 90%RH or less (non-condensing) | |

Altitude | ≤1000M: output rated power, >1000M: output derated | |

Storage temperature | -20℃~60℃ | |

Storage environment | Indoor, no direct sunlight, dust, corrosive gases, flammable gases, oil mist, steam, dripping, salt, vibration | |

IP protection level | IP20 |

Leave us Message