- 0755-21675210

- acdrive@micno.com.cn

2022-05-05

Abstract: this article mainly introduces the use of MICNO KE300A frequency converter in elevators, briefly describes the characteristics of KE300A frequency converter, the specific requirements of elevators for frequency conversion drive and other related precautions.

Keywords: MICNO, Elevator, KE300A

I. Introduction

The construction elevator is an indispensable and important construction equipment that cooperates with the large tower crane in the modern high-rise construction.

The current building construction elevators can be divided into three types according to the speed: low-speed elevators of 0 to 40m/min; medium-speed elevators of 0 to 63m/min; high-speed elevators of 0 to 96m/min.

Ⅱ. Analysis of disadvantages of traditional control of elevator equipment

The control method of ordinary elevators is realized by contactor, which has a single speed, poor comfort, large mechanical impact when power frequency starts and stops, which will cause serious damage to the structure and mechanism, and reduce the reliability of operation. Frequent start and stop and large current impact will easily reduce motor insulation and the service life of electrical components, resulting in high maintenance costs and device aging.

Ⅲ. Overview of elevator equipment

The parameters of the supporting motor (33KW/380V) of the on-site elevator at a construction site in Shenzhen: the equipment has a constant torque load. According to its working characteristics, the frequency converter with a higher level should be selected to ensure the safe, stable and fast operation of the system. The recommended configuration is as follows:

| No. | Model | Rated power | Rated voltage | Rated current | Quantity |

| 1 | KE300A-06-045G/055P-T4 | 45KW | 380V | 90A | 1 |

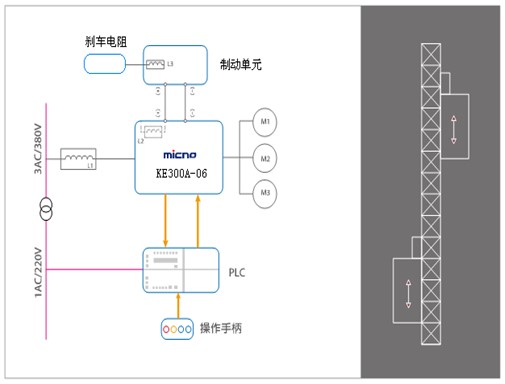

KE300A-06 series frequency converters have a professionally designed brake logic sequence control function, which ensures the comfort and safety of the brakes at the moment of opening. There is no "overshoot" phenomenon on the upward side, and no "weightlessness" on the downward side.

刹车电阻:Brake resistance

制动单元:Brake unit

操作手柄:Operating handle

The entire electric system consists of PLC, contactor, KE300A-06 frequency converter, brake unit, brake resistor, main drive motor, reduction box, brake, transformer, operating handle, etc., which control the operation of elevator, the open and close of brakes and perform various protections, so as to achieve efficient, safe and stable operation of the elevator.

n Control method

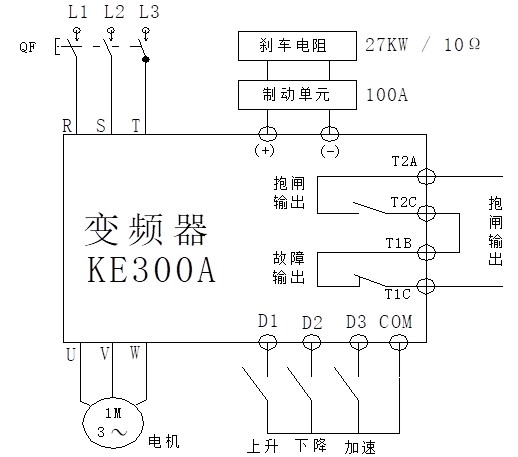

Since the elevator has a large inertial impact and generates regenerative energy, a brake resistor must be added to consume the regenerative energy. The details are shown in the following figure:

制动电阻:Brake resistance

制动单元:Braking uni

直流电抗器:Dc reactor

抱闸输出:Brake output

故障输出:Fault output

变频器:Frequency converter

电机:Motor

上升:Up

下降:Down

加速:Acceleration

Ø The control system of elevator gives the forward and reverse switching signals of the frequency converter: when the D1 terminal and the COM terminal are closed, the frequency converter will start to run forward (up); if it is disconnected, the frequency converter will be stopped; when the D2 terminal and the COM terminal are closed, the frequency converter will start to run in reverse (down), and if it is disconnected, the frequency converter will be stopped.

Ø The control system gives the switch signal to accelerate the frequency converter: when the D3 terminal and the COM terminal are closed, the frequency converter will accelerate.

Ø The frequency converter feeds back a normally open "brake output" switch signal to the control system. When the operating frequency of the frequency converter reaches the set value, the control system can release the holding brake to ensure that there is no "slip hook" phenomenon. At the same time, it is associated with the fault output of the frequency converter and outputs the normally closed signal. When a fault occurs, the brake signal can be disconnected.

Ⅳ. Parameter setting of the frequency converter

KE300A-06 series frequency converter has the function of improving the performance of brake. The specific function code:

| Function code | Name | Setting range | Factory default | Change |

| P5-03 | Relay T2 output selection | 45: Brake output | 0 | |

| A9-00 | The frequency of upward brake release | 0~20.00Hz | 3.00Hz | ◎ |

| A9-01 | The frequency of downward brake release | 0~20.00Hz | 3.00Hz | ◎ |

| A9-02 | Delay before releasing the brake | 0.0~3600.0S | 0.3S | |

| A9-03 | Delay after releasing the brake | 0.0~3600.0S | 0.3S | |

| A9-04 | The frequency of upward holding brake | 0~20.00Hz | 3.00Hz | |

| A9-05 | The frequency of downward holding brake | 0~20.00Hz | 2.50Hz | |

| A9-06 | Delay before holding brake | 0.0~3600.0S | 0.3 | |

| A9-07 | Delay after holding brake | 0.0~3600.0S | 0.3 | ◎ |

| A9-08 | Condition of releasing brake | 0: Frequency 1: Frequency and current | 1 | |

| A9-09 | Brake release current | 10.0~150.0 | 60.0 | |

| A9-10 | Zero-crossing speed acceleration time | 0.0~3600.0S | 2.0S | |

| A9-11 | Zero-crossing frequency range | 0~20.00Hz | 2.50Hz | |

| A9-12 | Judgment time for abnormal release current | 0.0~3600.0S | 2.0S |

n Description of function code

Ø A9-08 Condition for releasing brake

0: Frequency: brake release is only related to frequency arrival.

1: Frequency and current: the brake release is valid when the frequency and current arrive at the same time.

Ø A9-09 Release current: Used together with A9-08, when A9-08 is set to 1, it is the percentage of motor rated current (P1-03).

Ø A9-12: Judgment time for abnormal release current

When the output frequency reaches, but the output current does not reach the release current, after this time, the frequency converter trips for fault protection. At this time, you should check whether the motor wire is connected well.

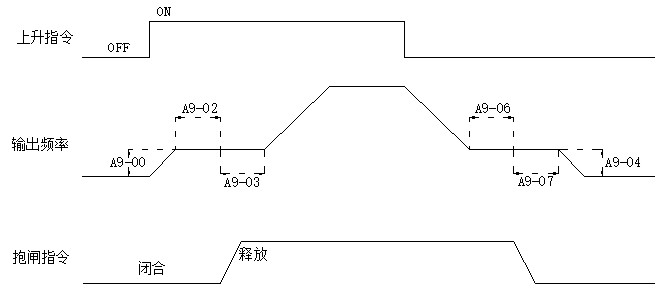

n Logic diagram of upward brake control

上升指令:Instruction for going upward

输出频率:Output frequency

抱闸指令:Instruction for holding brake

闭合:Closed

释放:Release

The detailed meaning of the above function codes is shown in the figure above. The brake logic when descending is similar to that when ascending, so the description is omitted.

n Parameter setting

Most of the parameters can be set according to the factory parameters. Users do not need to do too many complex settings when using, and only need to modify the simple parameters according to the actual use site. The specific parameter settings are as follows:

| Function code | Setting value | Function |

| P0-01 | 1 | Adopt vector control without PG |

| P0-02 | 1 | Terminal command channel |

| P0-03 | 6 | Multi-speed running setting |

| P0-17 | 10 | Acceleration time 1 |

| P0-18 | 10 | Deceleration time 1 |

| P2-10 | 200 | Torque upper limit setting |

| P4-00 | 1 | D1 terminal function: forward running |

| P4-01 | 2 | D2 terminal function: reverse running |

| P4-02 | 12 | D3 terminal function: acceleration operation, set frequency with PC-01 |

| P5-03 | 45 | Relay T2 output selection: brake output |

| P9-06 | 180 | Over-current stall protection current |

| PC-00 | 60 | Normal operating frequency, (percentage calculation) 50HZХ60%=30HZ |

| PC-01 | 100 | Acceleration operating frequency (percentage calculation) 50HZХ100%=50HZ |

Ⅴ. Advantages and characteristics of KE300A-06 frequency converter

The KE300A-06 frequency converter of MICNO has achieved very good results such as high efficiency and low failure rate in the field use, and has been unanimously recognized by customers. The advantages are summarized as follows:

(1) Compared with the traditional non-speed-regulated elevator, the ride comfort is greatly improved. It ensures the comfort and safety at the moment when the brake is opened, there is no "overshoot" phenomenon in the upward movement, and there is no "weightlessness" at the moment of downward movement.

(2) Since the system adopts the low-speed braking, the relative rotating friction of the brake is small, which greatly prolongs the service life of the brake.

(3) High low frequency torque.

(4) It effectively eliminates the transmission impact of the mechanism and prolongs the service life of gears, rollers, bearings and racks. Because the frequency conversion system has the function of current limiting, the impact current to the power grid when the motor is started is reduced, and the mutual influence between the electrical equipment is alleviated.

(5) The frequency conversion speed control system has perfect safety protection functions against under-voltage, over-voltage, over-torque, over-current, etc., to ensure the reliability and safety of the entire electronic control system.

Ⅵ. Conclusion

The application of MICNO KE300A-06 frequency converter in elevator actually solves the control problem of elevator very well. And the use of frequency converter control makes the system control simpler. The control system has multiple protections, which ensures the comfort and safety at the moment when the brake is opened. There is no "overshoot" phenomenon in the upward movement, and there is no "weightlessness" at the moment of downward movement. The system is more secure and reliable.