- 0755-21675210

- acdrive@micno.com.cn

2021-09-08

1. Introduction

Today in the 21st century, global energy is in short supply, and the call for energy conservation is getting louder. Advanced energy-saving technologies have gradually become a bright spot in society. However, in many energy-saving enterprises, especially in the ceramic industry, it is generally believed that ball mills are difficult to control, because the amount of electricity consumed by electrical equipment is determined by its electromechanical characteristics, and subjective control is meaningless. Obviously, this concept is wrong. Under the severe situation of power consumption across the country, MICNO frequency converters have adopted advanced frequency conversion and energy-saving technology to implement energy-saving transformation of ball mills at Xinhua Ceramics Factory in Foshan, Guangdong. Practice has proved that through a series of technical and management measures to minimize the energy consumption of the ball mill, that is, to protect the environment and create economic benefits for the company, the company can reduce operating costs by at least 5 to 10%.

2. Working principle of ball mill

The ball mill is mainly composed of a transmission equipment, a barrel equipment, a feeding equipment, a discharging equipment, and an electrical control equipment. It is divided into a feeding part, a discharging part, a rotating part, and a transmission part (reducer, small transmission gear, motor, electric control) and other main parts. Its main body is a low-speed rotating barrel mounted horizontally on two large bearings. The ball mill is decelerated and driven by a motor through a reducer and surrounding large gears, or is directly decelerated and driven by a low-speed synchronous motor through the surrounding large gears to drive the revolving part to rotate. A steel ball of a suitable grinding medium is equipped inside the barrel. The grinding medium is lifted to a certain height under the action of centrifugal force and frictional force, and falls in a state of throwing or venting. The material to be ground continuously enters the inside of the simplified body through the feed port, which is crushed by the moving grinding medium, and is discharged out of the machine through the force of overflow and continuous feeding for the next technological process.

The driving part is the key of the ball mill: the ball mill is a low-speed and heavy-duty equipment with a large load capacity and a large starting torque. Generally, a hydraulic coupler is required to complete the startup and speed control of the transmission system. The start of the ball mill has a great impact on the power grid, and the required torque is reduced after the start is completed, so there is a lot of room for energy saving. The currently commonly used driving method is three-phase AC motor-fluid coupling-gear reducer-pulley reducer. Because the ball mill has a constant torque load, when the hydraulic coupler is used for speed control, its speed control efficiency is equal to the speed control ratio, and a large part of the energy is wasted in the hydraulic coupler.

3. The production technology of the ball mill

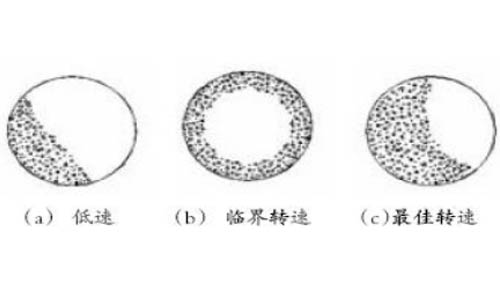

The ball mill generally runs at a fixed speed, and the rotate speed of the barrel is determined by the pulley or gear reduction mechanism (or the hydraulic coupler). The rotation speed of the ball mill directly affects the movement conditions of the steel balls and materials and the grinding process of the materials. At different rotation speeds, the movement conditions of the steel balls and materials in the barrel are shown in Figure 2.

(1) When the rotate speed is low, the steel ball and the material rise with the inner wall of the barrel. When the inclination angle of the steel ball and the material is equal to or greater than the natural inclination angle, they slide down the inclined surface, and a sufficient drop cannot be formed. The grinding effect of the steel ball on the material is very small, and the efficiency of the ball mill is very low.

(2) If the rotate speed of the barrel is very high, due to the centrifugal force, the material and the steel ball will no longer be separated from the barrel wall, but will rotate with it. At this time, the steel ball has no impact on the material and the grinding efficiency is much lower. The lowest speed in this state is called the critical speed.

(3) When the rotate speed of the barrel is at a certain point between the above two, the steel ball is brought to a certain height and then falls along the parabola, which has the greatest impact on the material at the bottom of the barrel and the grinding efficiency is the highest. The rotate speed at this time is called the optimal working speed.

4. The advantages of frequency converter transformation

Frequency conversion control technology is the most important technology for current electrical automation control. It has played an important role in equipment control in all walks of life. It is an inevitable development trend for ball mill applications, and it will definitely become the most important and most central part of ball mill process control automation. The use of frequency conversion control technology for the ball mill will brings about the following innovations:

(1) Improved power factor on the network side:

When the original motor is directly driven by the industrial frequency, the power factor is low at a light load (except for that with the compensation). After the frequency conversion speed control system is adopted, the power factor on the power supply side can be increased to more than 0.9, which can greatly reduce reactive power without a reactive power compensation equipment and meet the power grid requirements, thus further saving upstream equipment operating costs.

(2) Improve the use efficiency of the ball mill, save electric energy, and reduce equipment operating costs.

The most basic and most important point of the frequency conversion speed control technology is to achieve stepless speed control that cannot be achieved for the power frequency. It can realize the speed control below the power frequency for the ball mill equipment, so that the speed can adapt to the best working conditions. The barrel of the ball mill has a critical speed and an optimal working speed range. The performance of reaching or exceeding the critical speed is that the steel balls in the barrel will close to the inner wall of the barrel and rotate together and no longer break the material. Besides, within the optimal working speed range, the material handling capacity and efficiency are maximized in the barrel. Therefore, the actual rotate speed of the barrel will be controlled below the critical speed and work within the best working range as far as possible. The critical speed is related to the diameter of the barrel, the diameter of the steel ball, the weight and the dynamic filling rate of the material. The traditional power frequency control motor has a fixed rotate speed. When the speed does not meet the requirements of the critical speed, the critical speed can only be changed by changing the size of the steel ball and the material filling rate, which will seriously reduce the efficiency of the mechanical equipment and increase the production time (It takes time to add and replace steel balls and the amount of material that can be ground in the barrel for one time may not be maximized). After adopting frequency conversion speed control technology, the filling rate of different materials can be changed at will to make the ball mill run in the best working speed range: the operation is simple, the use efficiency of the ball mill will be greatly improved, and the operating cost will be saved at the same time. Moreover, the process of production tasks can also be guaranteed to the utmost. In addition, the use of frequency conversion speed control transmission equipment will also promote the great simplification of the mechanical transmission equipment in the future, and the mechanical loss will be further reduced, saving valuable electric energy.

(3) Save electricity through the V/F function of frequency conversion.

Under the condition of ensuring the output torque of the motor, the V/F curve can be automatically adjusted. Reduce the output torque of the motor, reduce the input current, and achieve an energy-saving state.

(4) The motor can be soft-started, and the current does not exceed 1.2 times the rated current of the motor when starting, and the service life of the motor is prolonged.

In the entire operating range, the motor current is small when starting, and the power consumption is 80% less than starting with a contactor, and the motor can ensure stable operation. It is self-evident that the large-inertia ball mill is damaged by the current impact during the traditional power frequency startup and the electrical transient during the shutdown. The frequency conversion speed control equipment has a good smooth control of the current during the startup and shutdown, which reduces the impact of starting current on the power grid, saves electricity bills, reduces the impact of starting inertia on the equipment's large inertia rotate speed, and prolongs the service life of the equipment.

(5) Powerful protection function, strong ability to adapt to voltage fluctuations of power grid.

The general protection function of the frequency conversion speed control equipment is comprehensive. It can prevent the sudden change of the grid from damaging the motor, effectively protect the frequency converter and the motor when the grid-side power fails, and effectively prevent the fault from spreading to the grid when the motor load fails, and can protect the motor to the utmost extent.

(6) The use of frequency conversion speed control equipment can improve the level of automation and provide a bottom solution for the factory to achieve a high degree of automation.

In the actual operation of the ball mill, there are often high noise and dust, and the workers should endure high work intensity and poor working environment. If the frequency conversion speed control equipment is used, the electric transmission equipment can be placed a little far away from the ball mill, which is more convenient and safe to operate. Data monitoring can also be carried out in an environment far away from noise.

5. Concluding remarks

In China's ceramic industry, ball mills are used in large quantities and are an indispensable and important production equipment for material crushing. Practice has proved that the MICNO KE300A frequency converter is very successful for the energy-saving drive of ball mills in the ceramic industry and has achieved good economic benefits. For the construction of a conservation-oriented society proposed by Chinese government, reducing environmental pollution is of great economic and social significance, and MICNO frequency converters will also be vigorously promoted and applied in the ceramic industry!