- 0755-21675210

- acdrive@micno.com.cn

2023-04-08

Energy is the foundation of modern industrial life, and oil is still the main energy source for industry. With the rapid development of China's economy, my country's oil consumption has increased significantly, and international oil prices are also in constant fluctuations. Energy industries such as oil and natural gas are taking a higher and higher status in the national economic industry, which widely affects the development of my country's economy. Effectively controlling the key technical links in the production process, improving the efficiency of oil and gas production, reducing energy consumption, and improving the overall informatization of oil fields are the current development trends of oil exploration operations.

The movement of the beam pumping unit is to lift up and down repeatedly, one time per stroke, and its power comes from two relatively heavy balance weights driven by the electric motor. When descending, the oil production rod is raised to bring oil to the wellhead. Due to the constant speed of the motor, when the slider is lowered, the load is lightened, and the energy generated by the motor dragging cannot be attracted by the load, causing the motor to enter the state of regenerative power generation, and the excess energy is fed back to the grid, causing the voltage of the main circuit bus to rise.It is bound to have an impact on the entire power grid, resulting in a decline in the power supply quality of the power grid, a decrease in power factor, frequent high-voltage shocks will damage the motor, shorten the life of the motor, and increase the amount of maintenance.

On the other hand, in order to overcome the large starting torque of the beam pumping unit, the motor used is far larger than the actual required power.The utilization rate of the motor is generally between 20% and 30% during operation, and the maximum will not exceed 50%., The motor is often in a light-load state, resulting in a waste of motor resources.And the working condition of the pumping unit changes continuously, which all depends on the state of the ground.If it is always in power frequency operation, it will inevitably cause a waste of electric energy.In order to save energy and improve the working efficiency of the motor, frequency conversion transformation is required.

Figure 1 beam pumping unit

驴头 Donkey Head

游梁 Walking Beam

横梁 Beam

悬绳器 Rope Hanger

支架 Bracket

平衡块 Balance Weight

连杆 Connecting Rod

曲柄 Crank

减速箱 Reduction Gearbox

皮带轮 Pulley

底座 Base

In order to feed back regenerative energy and improve efficiency, an energy feedback device is used to feed regenerative energy back to the grid.The so-called energy feedback device is actually an active inverter.According to the different power switching devices used, it can be divided into two types: thyristor (SCR) active inverter and insulated gate bipolar transistor (IGBT) inverter.Their common feature is that they can convert the voltage of the inverter DC circuit Feedback to the grid.

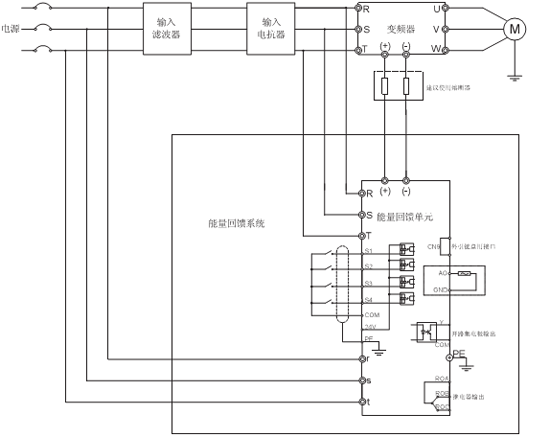

Figure 2 Inverter + Energy Feedback Unit

电源 Power Supply

输入滤波器 Input Filters

输入电抗器 Input reactor

变频器 Inverter

信息回馈系统 Information feed-back system

能量回馈单元 Energy feedback units

Features of the program

The dynamometer diagram of the pumping unit tested in the oil field shows that the digital pumping unit composed of frequency converter is running well, and the pumping unit is working in the best state.The inverter as a control solution has the following advantages in the application of digital pumping units:

The frequency conversion solution can make the pumping unit reach the best balance state according to the load of the oil well on site, make the pumping unit work at a reasonable stroke frequency according to the fluid production of the oil well, and adjust the pumping unit according to the working conditions of the oil well Carry out effective protection; thus maximally make the operating parameters of the pumping unit consistent with the parameters of the oil well, exert the working ability of the pumping unit, and realize low-carbon development and energy-saving mining;

The built-in communication function of the inverter provides RS485 communication interface, which makes the communication connection with the RTU control module easier;

Modular design, system maintenance is easier;

The inverter has various protection and fault output functions such as short circuit, overload, overvoltage, phase loss, stall, which can effectively ensure the safe and efficient operation of the system;

The parameter adjustment and management requirements of the frequency converter can be effectively realized through the station control platform, and the unattended well site in the true sense can be realized.

Customer feedback

In 2012, an oil production plant in Changqing Oilfield used 135 sets of energy feedback electromagnetic speed-regulating motors. After testing, the average active power saving rate per ton of liquid is 32%, the average reactive power saving rate per ton of liquid is 43%, the average power factor increases by 0.21, and the comprehensive power saving rate is 35%.The annual power-saving capacity is 4.56 million kwh, and the annual power-saving benefit is 3.2 million yuan.

With its superior performance, the KE300A series frequency converter of MICNO plays an important role in the energy-saving renovation of oilfields.The working intensity and time of sub-adjustment, and its energy feedback function optimizes energy saving.With the promotion of digitization and informatization in oilfields, KE300A series inverters will play an increasingly important role in the energy-saving transformation of pumping units.