- 0755-21675210

- acdrive@micno.com.cn

2021-08-23

1. Introduction

Sand is one of the most basic materials in the construction industry and is in great demand. How to obtain a large amount of sand to meet the needs of modern architecture? Among the many sand extraction equipment, the sand dredger is one of the most widely used equipment. Sand dredgers are mostly used for mobile operations, and the daily sand mining capacity of inland sand dredgers ranges from tens of tons to thousands of tons. Large-scale sand dredgers have a high degree of mechanization and automation, and a sand dredger can become a production unit, which can implement the whole process of sand mining and sand separation and selection.

2. Industry overview

The sand dredger is also known as the sand dredging machine and the sand picker. As the name suggests, it is a sand and gravel mining equipment, mostly for mobile operations. The daily sand mining capacity of inland sand dredgers ranges from dozens to thousands of tons. The hull adopts an assembled box structure. It is equipped with excavating equipment, screening equipment, lifting equipment, conveying equipment, etc. The digging and loading is driven by a motor, the stones are passed through the conveyor belt through the screening, and the sand is passed to the designated location by the conveyor belt.

3. Technological requirements and processes

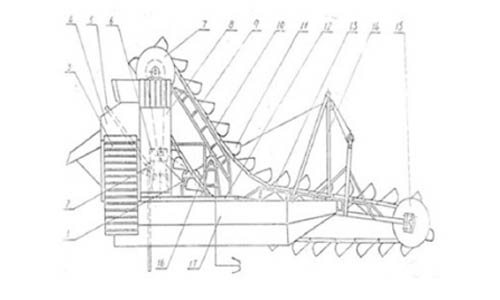

The following is a brief schematic diagram of a sand dredger, which consists of a digging equipment, a screening equipment, a lifting equipment, and a conveying equipment.

When the sand dredger is working, the motor drives the deceleration mechanism, and the deceleration mechanism drives the chain bucket. The chain bucket continues to go deep underwater to dig up sand and gravel, and then lift them to the on-board screening equipment to screen the impurities, and then transport them to the delivery ship by the conveyor belt and then to the shore.

When dredging the sand, the dredging speed must be determined according to the proportion of sand and gravel dug up. When there are more rocks, the speed is faster, and when there is more sand, the speed is slower, so as to prevent the sand from being washed away by currents.

4. The shortcomings of the original equipment: 8He Automation Online Network

Through the analysis of on-site equipment working conditions and the original control method, the following shortcomings are summarized: 8He Automation Online Network

(1): The rotate speed of bucket wheel needs to be adjusted manually according to the amount of sand extracted, and the amount of sand in the sand pit is uncertain, which increases the labor intensity of the workers on site. Frequent manual operations will also bring system instability and have an impact on the mechanical structure. Sometimes due to inaccurate judgment of the sand volume in the sand pit, or manual negligence to adjust the sand volume in a timely manner, too much sand in the bucket wheel may jam the conveying motor. 8He Automation Online Network

(2): The equipment startup circuit is complicated, which not only easily produces fault points, but also has a poor startup effect, which will affect the entire hull power supply and power generation equipment. 8He Automation Online Network

(3): The original control method does not have the ability of speed self-adaptation and closed-loop control. Manual adjustment will inevitably cause overshoot and waste electric energy, which increases the load of marine generators. 8He Automation Online Network

5. The advantages of using frequency conversion transformation

In view of the above situation, we have used frequency conversion technology to transform the many problems existing in the original speed regulation method of the bucket and conveyor belt of sand dredger.

(1) Use the soft start function of the frequency converter to reduce the impact on the bucket and belt, and at the same time reduce the current impact on the generator when starting the motor; the soft start current is only 0.5 times the auto-coupling step-down starting current, which not only improves the capacity of generator, but also reduces the damage of the circuit and the vibration of the hull when the motor is started.

(2) The frequency converter can be used to achieve stepless speed regulation. When the amount of sand pumping is insufficient, the output frequency of the frequency converter is reduced to allow the equipment to run at a low speed, which not only saves electricity, but also extracts the cleaned sand from the sand washing tank.

The frequency converter transforms the bucket and conveyor belt on the sand dredger, reduces the instantaneous impulse current when the motor starts, and solves the problems of traditional sand dredgers such as the inability to linearly adjust the speed, complicated operation and high labor intensity. After the sand dredger is transformed, it boasts advantages such as simple operation, high efficiency, lower energy consumption, more stable and reliable operation.

Note: Due to the heavy load, it is recommended to use the frequency converter in two steps; because the hull wiring is too long, it is easy to cause interference, and it is recommended to install an output reactor.

6. Summary

The frequency converter is used to transform the bucket wheel and conveyor belt on the sand dredger, which reduces the instantaneous impact current when the motor starts, and solves the problems of traditional sand dredgers such as the inability of linear speed regulation, complicated operation and high labor intensity. After the sand dredger is transformed, it boasts advantages such as simple operation, high efficiency, lower energy consumption, more stable and reliable operation.