- 0755-21675210

- acdrive@micno.com.cn

2022-04-15

Mixing machinery is widely used in the production process of chemical, pharmaceutical, food, water industry, plastics and other industries. In the design of mixing machinery, a certain margin should be considered according to the requirements of the working conditions. In the actual use of the mixer, it is not necessary to work under the maximum speed, and in most cases, it can work in non-full load state. Traditional mixers usually do not adjust or use mechanical method for speed regulation; mechanical method for speed regulation will increase the loss of the mixer, and at the same time make the mixer work In the fluctuating state, so as to make the mixer equipment work in the state of "big horse drawing small trolley", which is very uneconomical.

KE300A frequency converter is used to control the speed of AC motor. This speed regulation method boasts high efficiency and energy saving, which is better than any previous speed regulation method. Therefore, by installing it on the mixer equipment, many problems existing in the use of traditional mixers can be solved once and for all, and the investment can be recovered through energy saving.

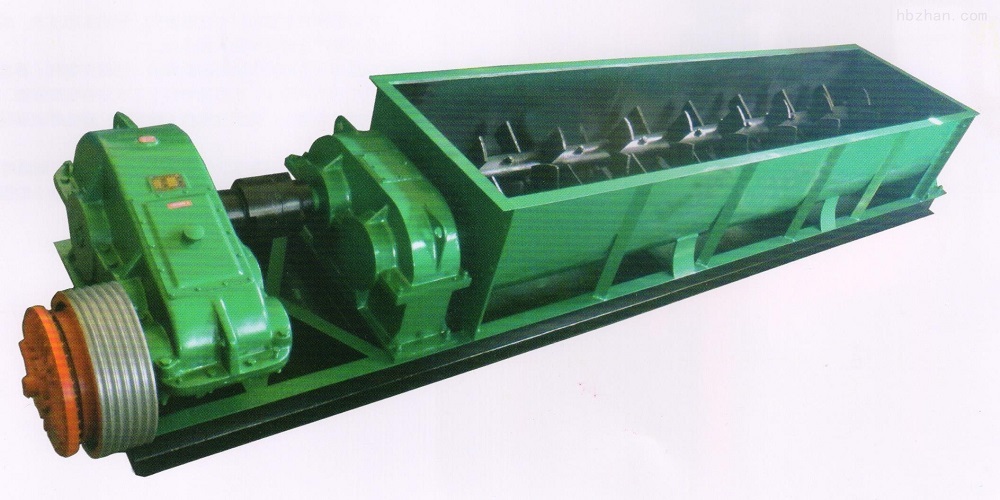

A mixer is a machine that rotates a variety of raw materials in a shaft with blades in a cylinder or tank to mix them into a mixture or a suitable consistency. According to the characteristics of the material to be stirred and the time for adding other substances, the required stirring speed is also different. At present, hydraulic coupling is used for stirring control. However, the hydraulic coupling is a mechanically inefficient speed regulation device, and there are still many defects:

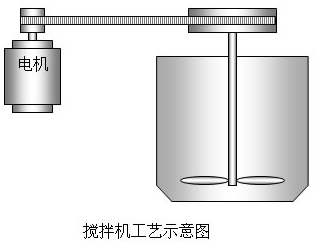

电机:Motor

搅拌机工艺示意图:Technological diagram of mixer

(1) The speed regulation range is narrow. The maximum speed regulation range of the hydraulic coupling is 4:1.

(2) The speed regulation accuracy is low. The speed regulation accuracy of hydraulic coupling is low, and the rotate speed fluctuates greatly.

(3) The efficiency of the hydraulic coupler is low, and its efficiency is proportional to the speed control ratio. The lower the rotate speed of the load, the lower the efficiency.

(4) Because the hydraulic coupling adopts the flexible connection, there is a fixed slip rate, that is, the slip rate of the hydraulic coupling is ≥3%, and the maximum can only reach 97% of the motor speed.

(5) The hydraulic coupler belongs to the direct starting type, and the starting current of the motor is about 4 to 7 times of the rated current, which causes a greater impact on the power grid.

(6) The reliability of the hydraulic coupling is poor. Especially problems such as oil leakage and broken gears will occur.

(7) The maintenance workload is heavy.

(8) Since the hydraulic coupler is connected between the motor and the fan, once the hydraulic coupler fails, the load cannot run and the continuity of production cannot be guaranteed.

Frequency conversion control technology is the most important technology in electrical automation control at present, and it has played an important role in equipment control in all walks of life. Its application in mixer is an inevitable development trend, and is bound to become the most important and core part of the automation of mixing technological control. Mixer using frequency conversion control technology will bring the following innovations:

(1) Energy saving through frequency conversion speed regulation:

In the actual work process, according to the characteristics of the stirring material and the time of adding other chemical substances, multiple speeds should be set, and up to eight different speeds can be achieved. At the same time, the program operation function of the frequency converter can also be used, and up to seven automatic program operation modes with different speeds and different times can be set, which greatly reduces the labor intensity of workers and improves production efficiency.

(2) The power factor of the grid side is improved:

When the original motor is directly driven by the power frequency, the power factor is low at light load (except for those with compensation). After adopting the frequency conversion speed regulation system, the power factor of the power supply side can be increased to more than 0.9, so reactive power can be greatly reduced without reactive power compensation device, which meets grid requirements and can further save operating costs of upstream equipment.

(3) Improve the use efficiency of the mixer, save electricity, reduce equipment operating costs, and ensure the maximum production task process.

The most basic and most important point in the frequency conversion speed regulation technology is to realize the stepless speed regulation that cannot be realized by the power frequency. It can realize the speed regulation of mixer equipment under the power frequency, so that the rotate speed can adapt to the best working condition, quickly adapt to the load change, and always keep the output of the motor running with high efficiency. Mechanical losses will be further reduced, saving valuable electrical energy.

(4) Save electricity through the V/F function of the frequency conversion itself

Under the condition of ensuring the output torque of the motor, the V/F curve can be automatically adjusted, so as to reduce the output torque of the motor, reduce the input current, and achieve an energy-saving state.

(5) The motor can be soft-started, the current at startup does not exceed 1.2 times the rated current of the motor, and the service life of the motor is prolonged.

In the entire operating range, the motor current is small when starting, and the power consumption is 80% smaller than that of starting with a contactor, and the motor can ensure smooth operation. It is self-evident that a mixer with large inertia will be damaged by current shock during startup at traditional power frequency and electrical transients during shutdown. The frequency conversion speed control device has a good smooth control of the current during startup and shutdown, reducing the impact of startup current on the power grid, saving electricity costs, reducing the impact of the starting inertia on the rotate speed of the equipment with large inertia, and prolonging the service life of the equipment.

(6) Powerful protection function and strong ability to adapt to grid voltage fluctuations.

The frequency conversion speed control device generally has comprehensive protection functions. It can prevent the damage to the motor caused by the sudden change of the power grid, effectively protect the frequency converter and the motor when the power supply on the grid side fails, and effectively prevent the fault from spreading to the power grid when the motor load fails, which can protect the motor to the greatest extent. It can automatically reduce the frequency when the mixer is overloaded to protect the normal operation of the equipment and the motor.

(7) The use of frequency conversion speed control device can improve the level of automation and provide the bottom solution for the realization of high automation in the factory.

In the actual operation of the mixer, it is often noisy and dusty, and the working intensity of the workers is high and the environment is poor. If the frequency conversion speed control device is used, the electrical transmission equipment can be placed a little far away from the mixer, which is more convenient and safe to operate. Real-time monitoring of data can also be performed in an environment away from noise.

With its excellent performance, KE300A frequency converter greatly improves the operation stability and safety of traditional mixers, and reduces maintenance work of equipment. The customized control system for mixers integrates many safety technologies and automatic control functions, providing a complete set of electronic control solutions for mixer equipment manufacturers, and can also rejuvenate old mixers. Since its launch, it has won unanimous praise from users, and has also solved the problem of backward electronic control of many machinery manufacturers, and achieved good social and economic benefits.