- 0755-21675210

- acdrive@micno.com.cn

2022-12-01

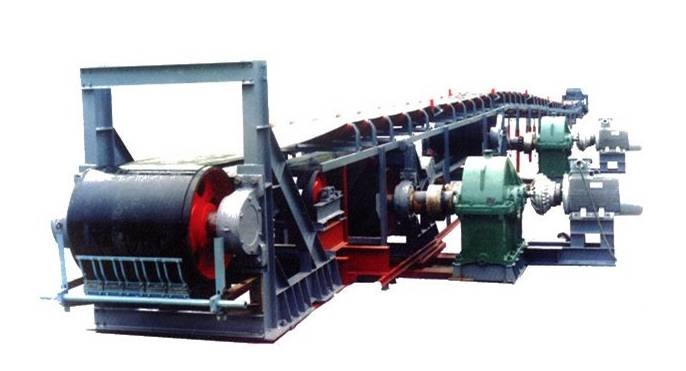

A conveyor belt, also known as a belt conveyor, is a continuous conveying machine and a universal machine. A conveyor belt consists of components such as a motor, a gearbox, a belt, a frame, a drive roller, a reversing roller, bearing rollers, return rollers, and a tensioning device. Generally, multiple motors drive a belt, and there is a high requirement for the power balance of multiple motors.

Excellent low-frequency torque characteristics, capable of heavy-load normal start-up;

Excellent master-slave control logic, capable of balancing the power of multiple motors;

Wide speed range, good soft start performance;

Good overload capacity and environmental adaptability, high operational reliability;

Wide input voltage range, automatic voltage adjustment function.

● The entire conveyor is driven in parallel by 4 motors, and the motors are connected to the conveyor drive roller through the reducer. The motor and the reducer, and the reducer and the drive roller are connected by a snake spring coupling. The motor uses coaxial motors, which means that 2 motors control one roller at the same time;

● The system is controlled by 2 KE300A frequency converters, each controlling four motors, that is, one frequency converter controls two motors, and one frequency converter is set as the host and the other as the slave. Through the master-slave control function of the frequency converter, the slave automatically follows the host's dynamic operation, thereby achieving power balance of four motors;

● The operation of the frequency conversion speed regulation system only requires operation of the host, which can be directly operated on the host through the built-in keyboard, or remotely controlled through the upper work platform.

● Slow start of the motor drives the belt conveyor to start slowly without causing damage to the belt, truly achieving soft start of the motor and belt conveyor in one;

● The equipment has stable start-up characteristics, greatly reducing the maintenance and repair workload of the equipment;

● Excellent master-slave control function, achieving power balance of four motors, and extending the service life of the motor;

● According to actual production conditions, the motor is speed-regulated, and the energy-saving effect is significant;

● Wide voltage network design of ±10%, meeting the power grid requirements in harsh environments.