- 0755-21675210

- acdrive@micno.com.cn

2023-03-22

With the rapid development of modern power electronic technology and microelectronic technology, frequency converter, as a product of modern industrial revolution, has been more and more applied to various fields of industrial production. From low voltage to high voltage, from ordinary to special, frequency converters play an irreplaceable role in speed regulation and energy saving, and are gradually expanding in depth. Now, in response to the request of the Changqing Oilfield Petroleum Administration Bureau's downhole operation branch, we have carried out frequency conversion transformation on its drilling equipment, the oil drilling rig, and have received good results.

1. Drilling purpose

Drive the drilling tool to break the rock, drill into the ground, and obtain oil or natural gas

2. Core action of rotary drilling rig

Rotary Drilling --- breaking rock

Mud circulation --- take away the broken rock

3. Core system

Lifting system, rotating system, mud circulation system

4. Core components required for core actions

Derrick, substructure, turntable, winch, crown block, traveling block, hook, swivel and mud pump

5. The on-site power system is provided by two 1000KW motors, and its main parameters are as follows :

Rated power | 1000kW | Rated voltage | 600V | rated current | 1205A |

Rated frequency | 60.5Hz | Rated speed | 1200r/min | Constant power maximum speed | 1500r/min |

Maximum speed | 1500r/min | Rated torque | 7958N.m | Rated efficiency | 94% |

Power factor | 0.85 | Insulation class | Level 200 | number of poles | 6 |

Working system | (S1) | cooling method | IC06 | degree of protection | IP44/IP54 |

Remark | Encoder (ZFL-H25-102.4BM-G8-26FD-5M-J (4-line incremental, OC) | ||||

With the continuous improvement of production efficiency, the requirements for drilling systems are also getting higher and higher. During the drilling process, the drill pipe needs to be lifted and lowered frequently. Due to the weight of the drilling tool, it is required to be stable and accurate in position. This is the general requirement for the drilling rig control system.

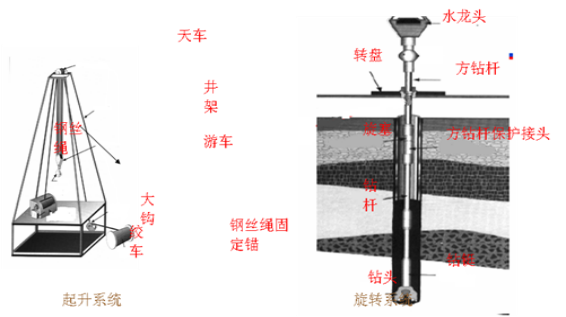

起升系统 Lifting system

钢丝绳 A wire rope

大钩 Hook

铰车 Reamer

天车 Crown block

井架 Derrick

游车 Traveling block

钢丝绳固定锚 Wire rope anchor

水龙头 Water tap

转盘 Turntable

方钻杆 Kelly

方钻杆保护接头 Kelly saver sub

旋塞 Cock

钻杆 Drill pipe

钻铤 Drill collar

钻头 Bit

旋转系统 Rotating system

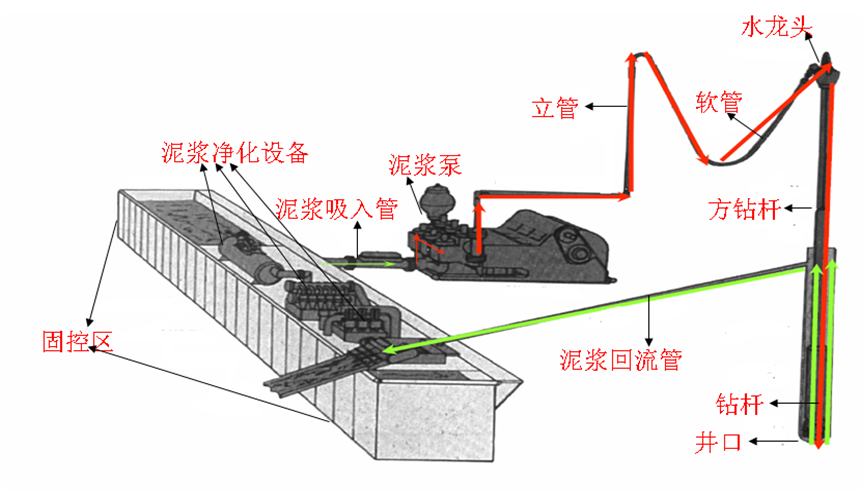

立管Riser

软管 Hose

泥浆净化设备Mud purification equipment

泥浆泵 Mud pump

固控区 Solid control area

泥浆吸入管 Mud suction pipe

泥浆回流管 Mud return pipe

井口 Wellhead

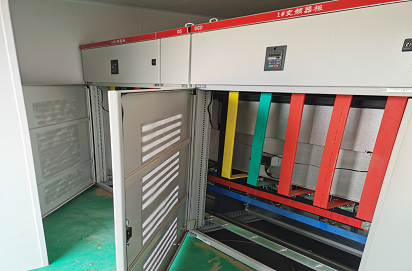

According to the special situation on site, we selected the KE300A-1200G-T6 (1200KW/660V) inverter independently developed and produced by our company.Its basic parameters are:

Input: three-phase, 660V, 50HZ

Output: three-phase, 0-660V, 0-60HZ

Frequency range: 0-60HZ

Maximum frequency: 33.5—300HZ can be set arbitrarily

Basic frequency: set arbitrarily between 0-60HZ

Starting frequency: 0—5HZ

Torque boost: adjust to the best according to the load torque

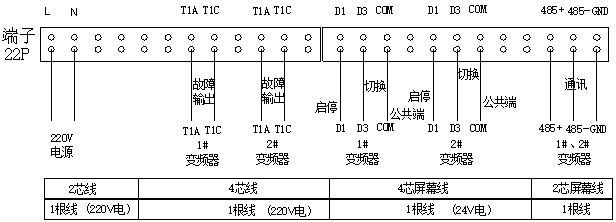

Wiring Instructions for Control Cabinet and Inverter

端子 Terminal

电源 Power supply

故障输出 Fault output

变频器 Frequency converter

启停 Start and stop

切换 Switch

公共端 Common terminal

通讯 Communication

芯线 Core wire

芯屏幕线 Core screen cable

1根线 1 wire

220V电 220V power

24V电 24V power

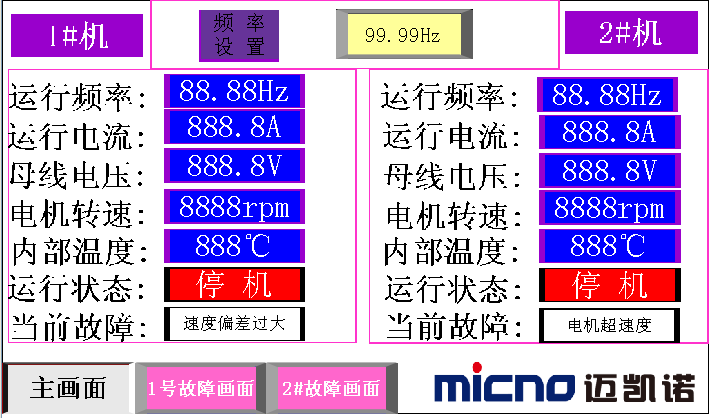

Touch screen operation instructions

运行频率 Operating frequency

运行电流 Operating current

母线电压 Bus voltage

电机转速 Motor speed

内部温度 Internal temperature

运行状态 Running state

当前故障 Current fault

频率设置 Frequency setting

停机 Shutdown

速度偏差过大 Excessive speed deviation

电机超速 Motor overspeed

主画面 Main screen

故障画面 Fault screen

After two months of trial operation, the system has shown obvious results:

1. Before the frequency converter is used, the lifting and lowering of the derrick is directly applied to the load through the gearbox at a power frequency of 50HZ.The speed is not controlled.The derrick itself is about 40 tons, and the large drilling rig is even heavier.The lifting and lowering is very unstable and the impact is large., is not easy to control.After using the frequency converter, it can start at low frequency 2-5HZ, the speed is slow, it is easy to operate and control the lifting position, and the low frequency lifting capacity is large, safe and reliable.

2. There are originally four gears when drilling a well, and there is no other speed selection.When the power frequency is 50HZ, the turntable is engaged and disengaged, which will have a great mechanical impact on the drill pipe, motor and gearbox.Especially when hitting rock formations, the underground geological conditions are complex and changeable, and the load is sometimes light and sometimes heavy, which makes the generator lose frequency and pressure, and the rotating speed of the turntable is sometimes fast and sometimes slow.When drilling a directional well, it will deviate from the design inclination.After the use of frequency conversion, the rotating speed of the turntable can be continuously adjusted within the set range, reducing frequent shifting, and the speed can be flexibly controlled according to the terrain.When the turntable drives the rotary rod, it can start at zero frequency, and the torque on the turntable is greatly reduced.The frequency converter Larger energy storage elements are also used to ensure load changes under complex and variable geological conditions.

3. With a large amount of oil extraction, the drilling depth is getting deeper and deeper.In this case, the rotary tool needs to be raised and lowered every 9 meters, and the lifting weight is getting heavier and heavier.Originally, the lifting tool needs to be replaced frequently.To adapt to heavier and heavier drilling tools, because the lifting speed is uncontrollable, when the drilling tool is stuck in the well, it will have a great impact on it, which may break the drill pipe and cause an accident.It can be lifted at low speed by using the frequency converter, and the lifting weight is large, and the impact force on the drilling tool is small.It is easy to control the position and speed of lifting and lowering, and is suitable for frequent lifting and lowering of drilling tools.

4. After using the frequency converter, the mechanical loss of the entire system is also reduced.The gearbox and braking system that were often damaged can reduce the number of maintenance times and reduce a lot of maintenance costs.The motor can be in a stopped state during drilling.However, when the motor is started directly at power frequency, the generator will be easily damaged if the starting current is large.The frequency converter can achieve continuous soft start, the starting current is small, and there is no impact on the generator set.It used to use more than 3 tons of oil per day, but now it uses about 2 tons of oil, so it also greatly saves energy.And we are also equipped with a set of power transformers so that they can be directly connected to the high-voltage grid for operation when conditions permit.

Oil drilling rigs adopt frequency conversion control, which is another successful application of emerging high-tech frequency conversion technology in oil fields.Through this practice, it is proved that the application of frequency converter is very extensive.We should seize this opportunity, strive to improve the technology and performance of this type of product, so that it can better meet the requirements of the site, and make greater efforts to expand the field of inverter update.