- 0755-21675210

- acdrive@micno.com.cn

2021-09-22

[Abstract] This article mainly introduces the energy saving of the MICNO KE300A frequency converter in the drying and ventilation system, and briefly describes the characteristics of the KE300A frequency converter, the specific requirements of the drying and ventilation system for the variable frequency drive and other related matters needing attention.

[Key words] MICNO, drying and ventilation system, KE300A, energy saving

Ⅰ. Introduction

China is a major producer and marketer of paper products in the world, and its total paper production and consumption rank first in the world. In recent years, China’s paper industry has integrated resources and eliminated outdated production capacity in accordance with the "Opinions of the China Paper Industry Association on the Development of the Paper Industry during the Thirteenth Five-Year Plan", and the supply capacity has fluctuated significantly.

The basic components of papermaking machinery are divided into wire, pressing, pre-drying, post-pressing, post-drying, calender, paper machine, etc. according to the order in which the paper is formed. The technology is that the pulp output from the headbox is dehydrated and formed in the wire section, compressed in the press section to make the paper layer uniform, dried through the pre-drying, then enters the post-press for sizing, and then enters the post-drying for drying treatment. Then the calender is used to smooth the paper, which finally passes through the paper reel to form a mother paper roll.

In the papermaking process, it is essentially a dehydration process, and drying and ventilation of paper is also one of the important links, accounting for most of the energy consumption of the entire papermaking process.

Ⅱ. Brief introduction to technological requirements of papermaking drying and ventilation system

In the drying section, all water vapor evaporated from the paper sheet is absorbed by the air and must be continuously removed from the papermaking workshop through forced ventilation. Whether the drying section is well ventilated or not directly affects the evaporation rate of the moisture in the paper sheet and the economy of the entire drying process; good ventilation can reduce the steam saturation in the air, thereby reducing the steam consumption of the dryer and speeding up the drying process.

Generally, in modern paper machines, forced air circulation is used to achieve high efficiency. Dry air heated to about 80 degrees is sent to the lower layer of the drying section with an air intake blower, so that hot steam is adsorbed between the dryers to form an upward airflow. Then the hot and humid air collected in the gas hood is drawn out of the outdoor through the exhaust fan (the waste heat is finally recovered). In high-speed paper machines, due to the increase in the number of dryers, they are usually divided into several sections of blower and exhaust fan groups.

Ⅲ. The necessity of the frequency conversion energy-saving transformation of the drying fan

(1) Introduction to the energy consumption of the drying fan

In the drying equipment, the fans generally used are relatively large, and the fans are almost continuously operated, otherwise it will directly affect the production process and economic operation. Fans commonly deployed in China are designed according to the maximum flow required under the maximum load, and the pressure and flow margin under the accident state are considered (that is, the corresponding insurance coefficient is added). The flow margin of the fan is 5 to 10%, and the pressure margin is 10 to 15%. In actual design, it is common for the flow and pressure margin to reach 20 to 30%. Therefore, the matching motor power of the fan is generally configured to be relatively large, which gives rise to the frequent phenomenon of waste capacity of fans. Besides, the degree of automation of the equipment operation is quite low, and it is almost completely adjusted manually. Due to the changes in working conditions and output, the air volume required by the system also changes. Most fans use the traditional method: the motor runs at full speed, the air volume is adjusted by adjusting the angle of the air door or blade. This method is time-consuming, laborious and difficult to master. The angle of the air door or blade is in one position for a long time. In addition, due to the effect of wind, it is easy to cause local deformation of the angle of the air door or the blades, and there may be jamming in the next operation, which will threaten safe production, and even waste a lot of electric energy.

The traditional adjustment system is realized by adjusting the angle of the air doors and blades according to the required air volume. From the process of fan selection and the actual production situation, the following problems exist in the constant speed operation of the fan:

(1) Serious waste of electric energy

Generally, the design of the drying fan has a large margin, so that the fan has been running under a relatively light load. Since the drying fan is generally adjusted by a baffle plate, it causes a waste of energy and increases the production cost.

(2) Difficult to start, serious mechanical damage

The drying fan has a long start-up time and a large start-up current, which poses a great threat to the insulation of the motor, and even burns the motor in severe cases. The single-axis torque phenomenon generated by the motor during the start-up process causes the fan to generate great mechanical vibration stress, which seriously affects the service life of the motor, fan and other machinery.

(3) Unable to achieve precise control

Due to the power frequency method, the control method of fixed angle of air door or blade, regarding the needs of work site and technologies, the air volume should be adjusted at any time to ensure the best technological requirements, but because it can only achieve fixed work, it cannot be accurately adjusted.

(4) Low degree of automation

The drying fan relies on manual adjustment of the baffle or blade angle, and does not have the function of automatic real-time adjustment of the air volume, and the degree of automation is low.

2. Analysis of the way to adjust the air volume of the drying fan

There are three main methods to change the flow of the drying fan: first of all, rotate speed of motor is constant, adjusting the opening degree of the valve (or air door); secondly, rotate speed of motor is constant, adjusting the opening degree of the fan blade; thirdly, the opening degree of valve (or air door) is constant, and the rotate speed of the motor is adjusted.

The following is an analysis of the power consumption and automation of the three methods:

(1) Comparison of adjustment methods of valve and rotate speed

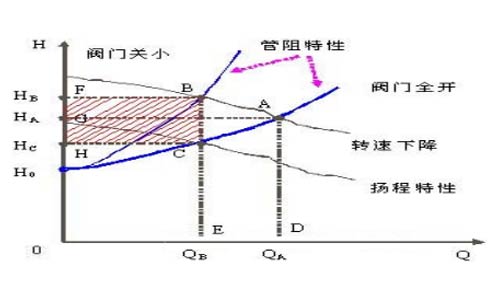

The valve adjustment method mainly adjusts the flow rate through the opening degree of valve, but actually changes the flow rate by changing the flow-resistance of the pipeline. When the valve is adjusted, the flow-resistance characteristics of pipeline change with the change of the valve opening degree, and the motor runs at a constant speed, so the pressure characteristic does not change. As shown in the figure below, when the flow rate drops from QA to QB, the stable operating point moves from point A to point B, and the power of fan PA is proportional to the area of the 0EBF area.

The rotate speed adjustment method is to change the flow rate by changing the rotate speed. The pipeline is generally in a fully open state. If the rotate speed of fan changes, the pressure also changes. When the speed adjustment method is used, the pressure changes with the speed, but the flow-resistance characteristics of the pipeline remain unchanged. As shown in the figure below, when the flow rate drops from QA to QB, the stable operating point moves from point A to point C, and the power of fan PB is proportional to the area of the 0ECH area.

It can be seen from the figure below that the power saved by the speed adjustment method compared to the valve adjustment method is proportional to the area of the HCBF area.

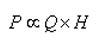

According to the principle of fluid mechanics, the relationship between shaft power P and flow Q and wind pressure H for a fan driven by an induction motor is:

When the rotate speed of motor changes from n1 to n2, the relationship between Q, H, P and the speed is as follows:

From the above derivation, it can be known that the energy-saving effect of using the speed adjustment method is better than that of the valve adjustment method.

(2) Comparison of adjustment methods of blade angle and rotate speed

When adjusting the flow rate by changing the angle of the fan blades, the pipeline is generally in a fully open state. If the angle of the fan blade changes, the pressure also changes. When the blade angle adjustment method is adopted, the pressure changes with the blade angle, but the flow-resistance characteristics of pipeline remain unchanged.

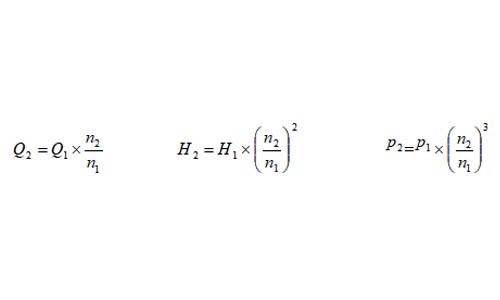

Characteristic curve of the drying fan

From the characteristic curve and flow-resistance curve of the drying fan in the above figure, it can be seen that the following problems exist in the comparison of the adjustment methods of blade angle and rotate speed:

(1) Due to the control method of fixed blade angle, there are a few effective divisions of the fan adjustment angle (the blade angle). During the later drying, the air volume required is the smallest, and the blade angle adjustment cannot meet the requirement of throttling air volume. Part of the air volume must be controlled through the valve, causing a lot of waste of electrical energy.

(2) The required air volume also needs to be adjusted continuously with the change of the production volume, the alternation of the four seasons, and the change of temperature. Because the blade angle adjustment relies on manual static adjustment of the blade angle, it does not have the function of online automatic real-time adjustment of the air volume. It also causes a lot of waste of electrical energy.

In summary, the use of frequency conversion speed adjustment method is more energy-saving than the use of fan blade angle adjustment method, and the degree of automation is improved.

Ⅳ. Overview of papermaking drying and ventilation system

(1) Company introduction

Guangdong Dingfeng Paper Co., Ltd. is located in Shouyue Village, Nanjie Town, Guangning County, Zhaoqing City, Guangdong Province, and is developed on the basis of the origin Guangning pulp mill, established and funded by the investment from Taiwan. It has more than 40 years of pulping experience, and currently produces an annual output of 250,000 tons of hardwood bleached wood pulp; 120,000 tons of wood-free paper and micro-coated paper, and has experience in package plant export and investing in establishing the entire plant in Indonesia. It can be described as a professional pulping manufacturer in Asia.

2. Project transformation plan of papermaking drying and ventilation system

After many investigations and comparisons, the user finally decided to adopt the KE300A series frequency converter speed control device independently developed and produced by Shenzhen MICNO Electric Co., Ltd. Through the cooperation of technical personnel of both parties, a frequency conversion transformation plan for the papermaking drying and ventilation system was jointly formulated. The transformation plan is as follows:

The configuration of frequency converter

Item; Parameter; Item; Parameter

The model of frequency converter; KE300A-250G/280P-T4; Rated capacity; 250KW

Rated voltage; 380KV; Rated current; 465A

The control mode of frequency converter

The monitoring computer of the remote operation console is used on the scene to carry out the DCS analog quantity setting method. When the frequency converter is running, the user can adjust the set frequency of the fan in the control room to meet the requirements of the working conditions according to the requirements on air volume and air pressure in the actual drying process.

Due to the wind pressure requirements of the fan, the operating frequency is generally above 35Hz. Therefore, the lower limit frequency of 35Hz is set in the control system to avoid entering the surge zone due to too small air volume.

Ⅴ. Energy-saving benefits

On-site data measured by the watt-hour meter is as follows:

| Serial number | Item detection | Valve adjustment | Frequency conversion adjustment |

1 | Day power consumption | 5236.32 degrees | 3851.52 degrees |

| 2 | After the transformation | the power saving rate is 26.44% | |

| 3 | Operating time | 300 days per year | |

| 4 | The unit price of electricity | 0.72 yuan/KW/h | |

| 5 | Annual operation saves | 415,300 kWh of electricity | |

| 6 | Annual operation energy-saving benefits | 299,900 yuan | |

It can be seen that after investing in a KE300A series frequency converter produced by Shenzhen MICNO Electric Co., Ltd., the project can save about 290,000 yuan in electricity bills throughout the year. In addition, because the power factor of the KE300A series frequency converter produced by Shenzhen MICNO Electric Co., Ltd. can reach more than 0.95, which is greater than the motor power factor of 0.89, a large amount of reactive power is reduced. In addition, the soft start of the motor can be realized, which can avoid the impact on the motor insulation caused by the impact of high current start, reduce the maintenance of the motor, save the maintenance cost, and greatly extend the service life of the motor. Besides, it reduces the labor intensity of the operating personnel and is well received by the operating personnel and maintenance personnel.

Ⅵ. Summary of frequency conversion transformation

According to the installation and use of our company's frequency converters in various fields, we conclude that frequency converter transformation has the following advantages:

(1) The installation is simple, that is, the frequency converter is inserted between the original switch cabinet and the motor, and the original wiring is not changed.

(2) The operation is convenient, and the frequency converter operation only has simple startup, shutdown and frequency adjustment.

(3) It can carry out stepless speed control with a wide speed control range, high speed control precision and strong applicability.

(4) Perfect protection function, low failure rate, smooth start of the fan, low starting current and high reliability.

(5) The motor does not need long-term high-speed operation, the working current is greatly reduced, and the power saving effect is significant.

(6) Since the frequency converter replaces the valve speed control, the defects of high failure rate of machinery and pressure are eliminated, and the equipment maintenance cost is reduced.

(7) The vibration and noise of the motor are significantly reduced, and the temperature of the bearing is also greatly reduced.

(8) The AC variable frequency speed controller is welcomed by users for its strong applicability, high reliability, and easy operation and use. It is used in speed control, power saving, soft start, and has great practical value for enterprises.

Ⅶ. Concluding remarks

The energy-saving effect of the frequency conversion device is obvious. After the frequency conversion speed control system is adopted, the soft start of the motor is realized, the service life of the motor is prolonged, and the vibration and wear of the pipeline are also reduced; The KE300A series frequency converter speed control device independently developed and produced by Shenzhen MICNO Electric Co., Ltd. has been successfully applied in the speed control transformation of the papermaking drying and ventilation system in Guangdong Dingfeng Paper Co., Ltd. The advancement and reliability of this series of frequency converters have been confirmed by many industrial applications.