- 0755-21675213

- acdrive@micno.com.cn

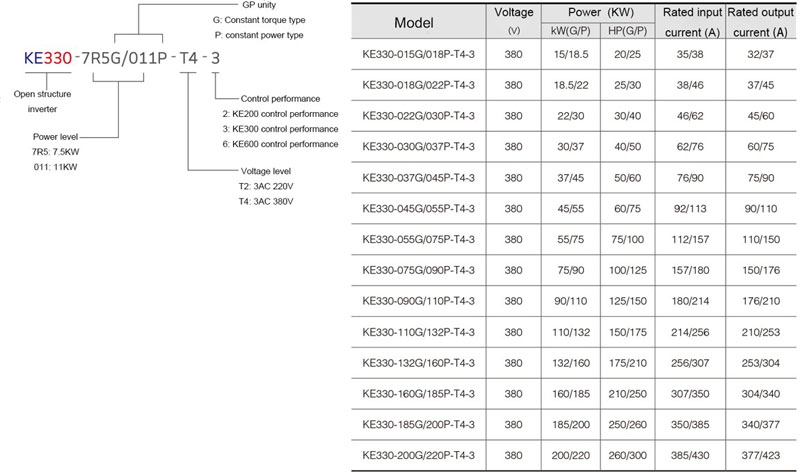

KE330 Open Structure Inverter to meet the rapid development of market especially the demands of OEM customers, MICNO launched the new model "KE330 open structure frequency inverter", which equipped with the same function and performance as KE300 or KE600, only the structure design is changed into open structure instead of a close one. As its structure is open, this inverter does not qualify any waterproof and dustproof ability, which must be installed inside an electronic cabinet.

The KE330 open structure inverter consists of two parts: the movement and the radiator.

Mainly targeted at the supporting market applications and OEM customers.

Input | Input voltage | 1AC 220V±15%,3AC 220V±15%,3AC 380V±15%,3AC 660V±15% |

Input frequency | 47~63Hz | |

Output | Output voltage | 0~rated input voltage |

Output frequency | V/f control:0~3000Hz;Sensorless vector control:0~300Hz | |

Control Features | Control mode | V/f control Sensorless vector control Torque control |

Operation command mode | Keypad control Terminal control Serial communication control | |

Frequency setting mode | Digital setting, analog setting, pulse frequency setting, serial communication setting, multi-step speed setting & simple PLC, PID setting, etc. These frequency settings can be combined & switched in various modes. | |

Overload capacity | G model: 150% 60s, 180% 10s, 200% 3s P model: 120% 60s, 150% 10s, 180% 3s | |

Starting torque | 0.5Hz/150% (SVC),1Hz/150% (V/f) | |

Speed adjustment range | 1:100 (SVC),1:50(V/f) | |

Speed control precision | ±0.5%(SVC) | |

Carrier frequency | 1.0--16.0kHz, automatically adjusted according to temperature and load characteristics | |

Frequency accuracy | Digital setting: 0.01Hz Analog setting: maximum frequency * 0.05% | |

Torque boost | Automatically torque boost; manually torque boost: 0.1%~30.0% | |

V/f curve | Three types: linear, multiple point and square type (1.2 power, 1.4 power, 1.6 power, 1.8 power, square) | |

Acceleration/decele ration mode | Straight line/S curve; four kinds of acceleration/deceleration time, range: 0.1s~3600.0s | |

DC braking | DC braking when starting and stopping DC braking frequency:0.0Hz~maximum frequency, braking time: 0.0s~100.0s | |

Jog operation | Jog operation frequency: 0.0Hz~maximum frequency Jog acceleration/deceleration time:0.1s~3600.0s | |

Simple PLC & multi-step speed operation | It can realize a maximum of 16 segments speed running via the built-in PLC or control terminal. | |

Built-in PID | Built-in PID control to easily realize the close loop control of the process parameters (such as pressure, temperature, flow, etc.) | |

Automatic voltage regulation | Keep output voltage constant automatically when input voltage fluctuating | |

Control Function | Common DC bus | Common DC bus for several inverters, energy balanced automatically |

Torque control | Torque control without PG | |

Torque limit | "Rooter" characteristics, limit the torque automatically and prevent frequent over-current tripping during the running process | |

Wobble frequency control | Multiple triangular-wave frequency control, special for textile | |

Timing/length/counting control | Timing/length/counting control function | |

Over-voltage & over-current stall control | Limit current & voltage automatically during the running process, prevent frequent over-current & over-voltage tripping | |

Fault protection function | Up to 30 fault protections including over-current, over-voltage, under-voltage, overheating, default phase, overload, shortcut, etc., can record the detailed running status during failure & has fault automatic reset function | |

Input/output terminals | Input terminals | Programmable DI: 7 on-off inputs, 1 high-speed pulse input 2 programmable AI: A12: 0~10V or 0/4~20mA |

Output terminals | 1 programmable open collector output: 1 analog output (open collector output or high-speed pulse output) 2 relay output 2 analog output: 0/4~20mA or 0~10V | |

Communication terminals | Offer RS485 communication interface, support MODBUS-RTU communication protocol | |

Human machine interface | LED display | Display frequency setting, output frequency, output voltage, output current, etc. |

Multifunction key | QUICK/JOG key, can be used as multifunction key | |

Powerful PC control software | Micno host computer control software, support uploading, downloading and real-time display with PC | |

Environment | Ambient temperature | -10℃~40℃, derated 4% when the temperature rise by every 1℃(40℃~50℃). |

Humidity | 90%RH or less (non-condensing) | |

Altitude | ≤1000M: output rated power, >1000M: output derated | |

Storage temperature | -20℃~60℃ | |

Storage environment | Indoor, no direct sunlight, dust, corrosive gases, flammable gases, oil mist, steam, dripping, salt, vibration |

Leave us Message